The problem

Ear and nose reconstructions are performed by highly skilled reconstructive surgeons who use a patient's own rib cartilage, and carves it by hand, like a sculptor, to achieve the final ear/nose framework.

This process:

This process:

- Is highly prone to error and variability between surgeons and even patients of the same surgeon

- Is with limited room for revision due to a finite amount of substrate rib cartilage harvested as part of the operation

- Has high cosmetic and functional implications for suboptimal implications.

- Is time-consuming (increasing procedural cost)

- Requires highly specialized surgical skills, making patient access to this procedure limited

Our insights:

- Consistency of ear and nose shapes across patients supports a simplified and more automated carving process.

- Inefficiency in cartilage carving increases costs across multiple surgical parameters. Speeding up this process generates value for not only the patient, but the healthcare system.

- Optimal results every time in a standardized manner ensures that all patients can receive functionally and cosmetically appealing results.

- The hand-carving step precludes other trained surgeons from performing this procedure in medically underserved regions.

Our solution: AuryzoN

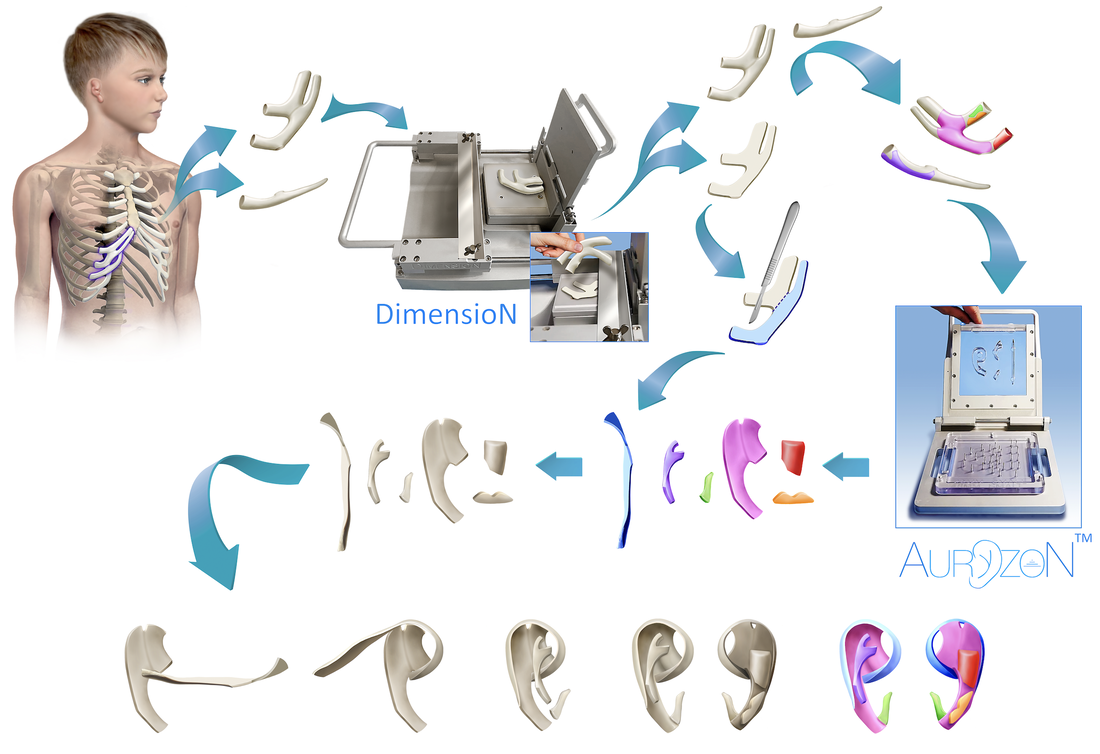

The AuryzoN Process

- Costal cartilage is harvested by standard surgical technique.

- The cartilage is thinned to specified measurements using the DimensioN device, which also increases the effective amount of cartilage multiple-fold, by creating even-plane cuts of the original substrate.

- The thinned cartilage is placed on a guide cassette in the AuryzoN device, and subsequently cut by the specific cutter cassette suited for the size of the desired ear.

- The cut shapes are then assembled into the auricular superstructure using metal sutures and other fixation materials.

- The completed construct may then be implanted in the surgical bed using standard technique.

AuryzoN and DimensioN Instructions for Use (IFUs)

Please click the link below to download our device IFUs:

| auryzon_dimension_ifus.pdf | |

| File Size: | 1121 kb |

| File Type: | |